Sunday, September 07, 2008

Some Facts on Agri-produce Storage Scenario, Wastages & New Initiatives

Development and management of marketing infrastructure is one of the main concerns of agriculture in India. Infrastructure is gaining increased attention in the wake of global food scenario, ushering the second green revolution, enhancing incomes & living standards of farmers and ensuring food security in the country and reducing the enormous wastages evident in the food chain. These challenges facing Indian agriculture are more pronounced than ever before and are being compounded by the rising income levels coupled with changes in dietary habits of the consuming class, dependence of a high proportion India’s working population on agriculture and nearly stagnant agriculture growth.

Unlike developed countries, the farming in India is fragmented with a big majority of farmers falling under the small & medium category. Moreover, with the declining average landholding size in the country (presently standing at about 1.06 hectares in 2006 as compared to 2.3 hectares in 1970 – 71) renders a drawback on the risk taking abilities of farmers, and consequently manifests itself in form of distress sales due to the need for ready cash after harvest. Evidently, there is a need for a mechanism to enable farmers to store their produce for sale at best time, achieve reduction in agri-produce wastage, maintain quality and at the same time ensure that farmers avail themselves of with credit facilities for their short term monetary needs.

It has been estimated that effective price realizations from the sale of agri-produce by farmers range between 30-40 percent. The remaining gets appropriated across the various intermediaries existing in the Indian Agri-value chain. One of the severest drawbacks facing farmers in India, is their inability to manage post harvest stocks, as indicated previously, most of the farmers belong to the small & medium farmer category, which promotes a high degree of risk aversion as well as the ability to invest in the development of storage infrastructure at farm level. Consequently, farmers tend to dispose of products at throw-away prices.

Amazing facts on agri-produce wastage in India

Storage woes: Of total production, about 60% is retained and stored by the farmers for consumption, seed, feed and payment of wages to laborers. Nearly 30 percent of the produce is stored under open conditions, leading to wastage and distress sales. Most farmers store foodgrains and oilseeds in gunny bags, mud bins, baked earthen containers; in heaps on flat floor; bamboo structures; wooden bins and underground structures. As these are not scientific ways of storing food grains, nearly 5-10% losses in quantitative terms are incurred during storage period of 3-8 months, especially during rainy season. The remaining 40% produce, which is the marketable surplus, is handled by traders and Government agencies. The marketable surplus too is prone to enormous wastages. It has been estimated that nearly 12% of the post harvest stock stored in public warehouses gets wasted due to lack of quality storage. Preventable post-harvest losses of foodgrains are estimated at about 20 million tonnes a year, which is nearly 10.5% of the total production.

Infrastructure Issues: The paucity of infrastructure facilities like roads, cold chains and especially storage facilities becomes apparent in huge wastages of agricultural produce of the country.

Roads: India has the largest road network in the world, aggregating around 3.32 million kilometers it consists of 65,569 km of National Highways, 1,28,000 km of State Highways, 4,70,000km of Major District Roads and 26,50,000 km of other District and Rural Roads. Yet still, our capacity is much below the level expected for efficient transfer of goods from one place to another. National Highways account for only 2 per cent of the total length of roads carry about 40 per cent of the total traffic across the length and breadth of the country. Further, programmes on rural road connectivity mostly concentrate linking the villages, which for one, is important. Yet from agriculture marketing aspect, availability of efficient infrastructure to connect farm produce to the collection centres / mandi is absent. Providing farm roads not only helps in transportation of the farm produce without loss of time and therefore protecting the quality of the produce, it also helps in maintaining the quality of perishables. Since, handling of the perishables is still in primitive stages i.e. more often stuffed in gunny bags, or tightly packed in the baskets and staked one above the other, the quality of the road decide the extent of the damage to the produce.

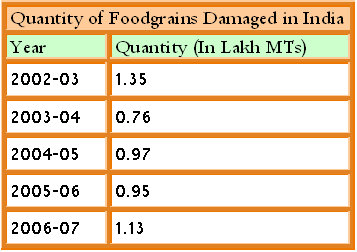

The government, last year, admitted that as much as Rs 58000 crores worth of agriculture produce is lost due to absence of proper infrastructure, and in case of perishables like fruits & vegetables, nearly 25 – 30 percent of goods are lost in absence of adequate infrastructure. Over the years since 2003-04 it has been estimated that quantity of food grains damaged in India is increasing.

Source: Department of Food and Public Distribution, Ministry of Consumer Affairs, Food and Public Distribution, Government of India

Inadequate Cold Chain Infrastructure: Until a few years back, cold chain network in India was practically non-existent and moreover, stand alone cold storage were passed of as cold chain network. As on December 2006, 5,101 cold stores in India with a total capacity of 21.7 million metric tonnes were operational in India. Out of the total cold storage capacity in the country, nearly 66 per cent (14.27 million MT) is confined to two states i.e. Uttar Pradesh and West Bengal with UP having 41 per cent of the total installed capacity. In terms of products, nearly 78 per cent of the cold storage capacity was utilized for potato and potato seeds (which according to estimates is still inadequate, presently standing at about 42 percent of the total cold storage requirement for potato) and only about 0.4 per cent was used for fruits and vegetables. Technology utilised in most cold storages are archaic and there is a need for involving new and innovation techniques to save on cost and improve shelf life. At present single chambered, single product facilities are utilised to stock potato and seed potato for about 6 months a year and lie idle during the rest of the year. Consequently, there is a need for multi commodity cold storages with latest facilities for quality control, and processing & packing. A detailed analysis of the warehousing structure in the country has been undertaken in the following section.

to be continued.....

No comments yet